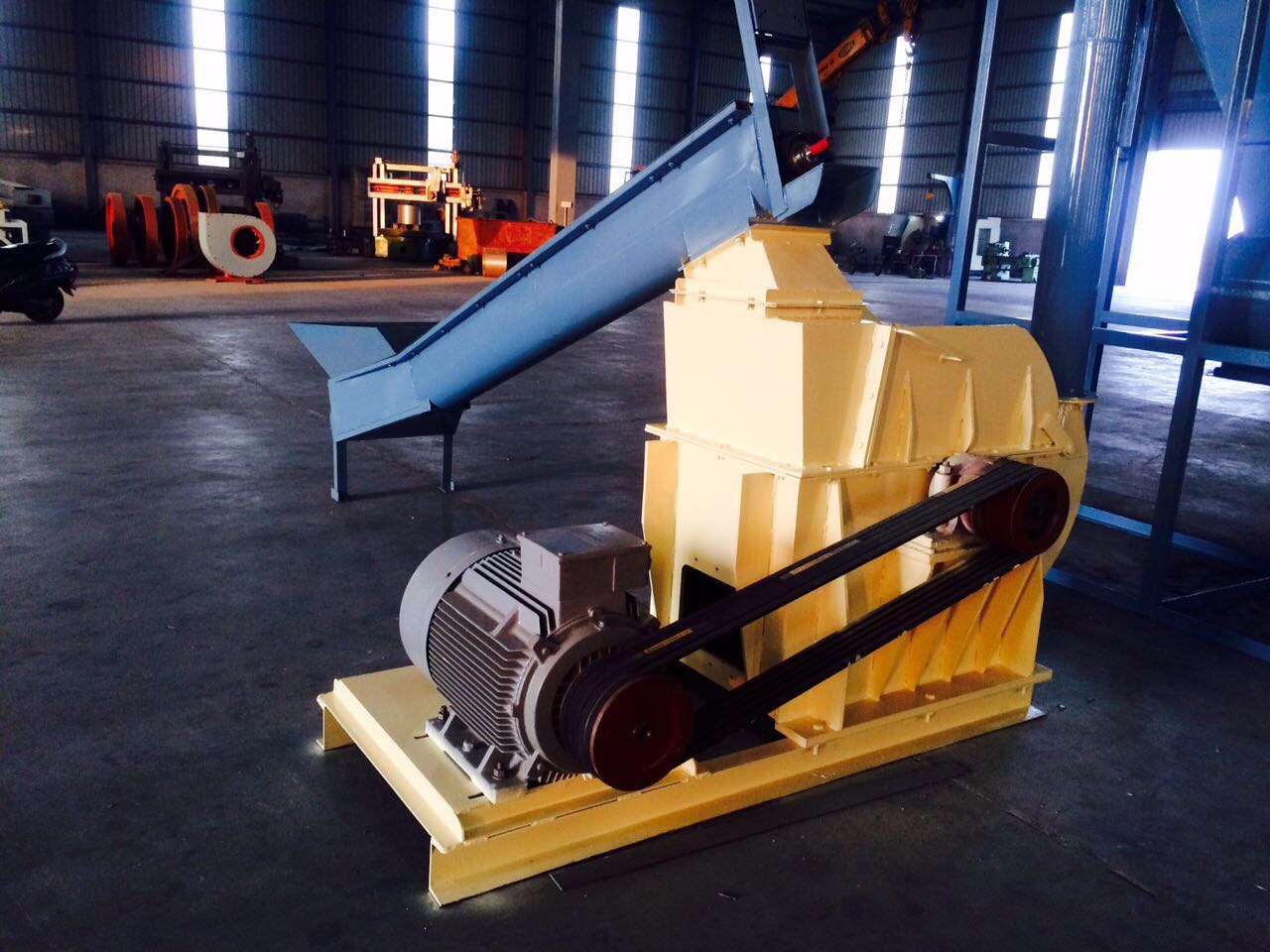

Hammer Mill Grinder

Hammer Mill is used for grinding of biomass waste & residues such as rice husk, groundnut shell, wood chips, cotton shell, mustard husk, sugar canetrash & bagasse etc. Hammer Mill Grinder has large diameter dynamically balanced rotor. Its body is made from tested plate, alloy steel shaft. For long life bearings are width, dust protected and Itted away from grinder body guarantees continuous production and performance.

Grinder blades are Itted with rotor. At bottom screen is Itted for particular size of ground material. Balanced Hammer system ensures silent running.Material is fed through feeding conveyor into wide in-feed opening of Hammer Mill. Swinging hammer takes the material into grinding chamber to crush the material on to the stationary liners before driving them through a screen at the bottom. Size of screen and hammers determine the size of crushed particles. Material at bottom is sucked by pneumatic system and conveyed to cyclone. Material is then ready for densiIcation by briquetting.

Hammer Mill Grinder |

|

| Power | |

| 1200 Kg/H | 34 hp |

| 1800 Kg/H | 41 hp |

| 2500 Kg/H | 51.5 hp |

| 5000 Kg/H | 105 hp |