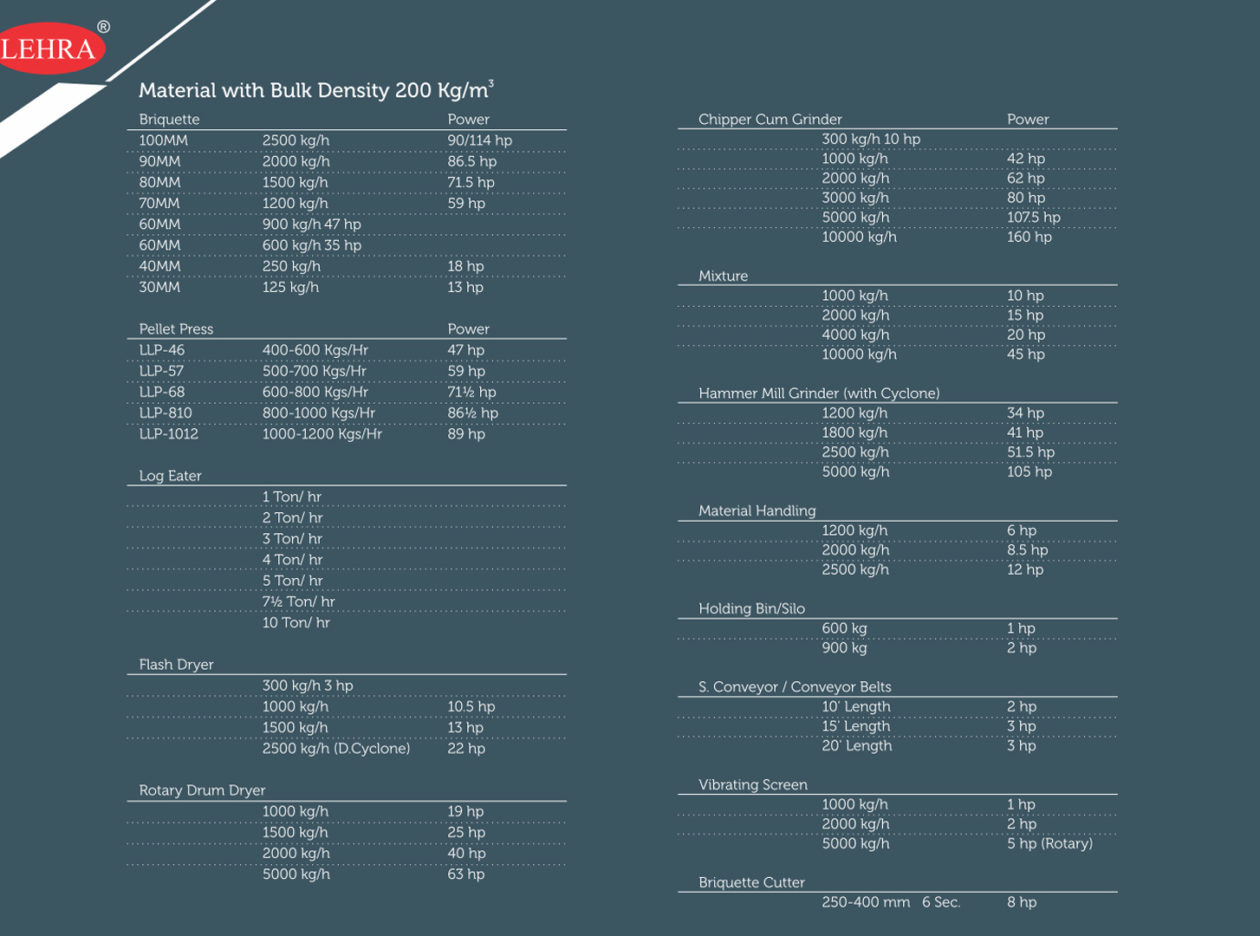

Every year millions of tons of agricultural wastes are generated which are either destroyed or burnt inefficiently in loose form causing air pollution. These wastes can can be recycled & can provide a renewable source of energy by converting biomass waste into high density – fuel briquettes without addition of any binder.

We’re on Call 9am to 6pm

+91 991 520 0537

Operating Hours

Mon - Sat 08:30 - 18:00

Mail Us

info@lehrafuel.com